How Do You Tension a Wire Mesh Fence?

Wire mesh fences are widely used for various applications, including securing properties, enclosing livestock, and enhancing safety. Proper tensioning of a wire mesh fence is crucial to ensure its longevity, functionality, and aesthetic appeal. This essay explores the step-by-step process of tensioning a wire mesh fence, highlighting the necessary tools and techniques, and emphasizing the benefits of proper tensioning.

Understanding the Importance of Tensioning

Tensioning a wire mesh fence is essential to maintain its structural integrity and effectiveness. A well-tensioned fence provides the following benefits:

Durability: Proper tensioning prevents sagging and reduces wear and tear, extending the fence's lifespan.

Security: A taut fence is harder to breach, offering better security for enclosed areas.

Aesthetic Appeal: Even tensioning ensures the fence looks neat and professional.

Functionality: For applications like livestock enclosures, a well-tensioned fence prevents animals from escaping or damaging the fence.

Preparation: Tools and Materials

Before tensioning a wire mesh fence, gather the necessary tools and materials:

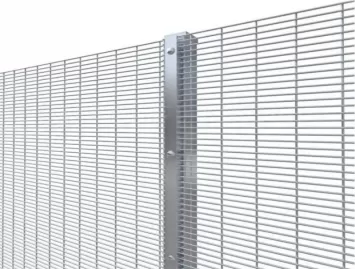

Wire mesh rolls

Fence posts (wooden or metal)

Post hole digger or auger

Concrete (if setting posts in concrete)

Tensioning tools (come-along, wire strainers, or ratchet tensioners)

Further reading:

Benefits and Applications of Epoxy Coated Wire Mesh

Revolutionize Your Filtration System with High Silica Fiberglass Mesh Cap – Available for Sale Now!

Is Porous Cardboard the Next Eco-Friendly Revolution?

Fiberglass Filter Prices: Are Quality Filters Worth It?

Are Investment Casting Filters Worth the Hype?

Ultimate Guide: Silica Fiberglass Filtration Filter for Steel

Silicon Carbide (Sic) Ceramic Foam Filter for Copper and Iron Price: Everything You Need to KnowFence clips or ties

Hammer and nails or screws

Pliers and wire cutters

Measuring tape

Level

Step-by-Step Guide to Tensioning a Wire Mesh Fence

Plan the Fence Layout: Begin by planning the layout of your fence. Mark the locations for corner posts, end posts, and line posts. Ensure the distances between posts are consistent to provide uniform support.

Install Corner and End Posts: Corner and end posts are crucial for tensioning as they bear the brunt of the tensioning force. Dig holes for these posts using a post hole digger or auger. The holes should be deep enough to support the posts firmly (at least one-third of the post length). Set the posts in concrete for added stability and allow them to cure.

Install Line Posts: Line posts provide additional support to the wire mesh. Install them at regular intervals (typically 8-10 feet apart). Ensure they are aligned and level with the corner and end posts.

Attach the Wire Mesh to Corner Posts: Unroll the wire mesh along the length of the fence line. Attach one end of the mesh to a corner or end post using fence clips, ties, or staples. Start from the top and work your way down, ensuring the mesh is evenly distributed.

Tension the Wire Mesh: Use a tensioning tool like a come-along, wire strainer, or ratchet tensioner to apply tension to the wire mesh. Attach the tool to the mesh and the opposite corner or end post. Gradually apply tension, ensuring the mesh remains level and aligned. Check the tension periodically to avoid over-tightening, which can damage the mesh.

Secure the Tensioned Mesh: Once the desired tension is achieved, secure the mesh to the opposite corner or end post. Use fence clips, ties, or staples to fasten the mesh, starting from the top and working downward. Ensure the mesh is taut and evenly attached.

Attach the Mesh to Line Posts: Secure the wire mesh to the line posts using fence clips or ties. This step provides additional support and maintains the tension along the entire fence line. Make sure the mesh is attached firmly to prevent sagging.

Inspect and Adjust: After tensioning and securing the wire mesh, inspect the entire fence line. Check for any areas where the mesh may have loosened or sagged. Make necessary adjustments to ensure the fence is uniformly tensioned and properly aligned.

Conclusion

Tensioning a wire mesh fence is a critical step in ensuring its durability, security, and functionality. By following a systematic approach and using the right tools, you can achieve a well-tensioned fence that meets your needs. Proper tensioning not only enhances the fence's performance but also contributes to its aesthetic appeal, making it a reliable and attractive solution for various applications. Whether for residential, agricultural, or industrial use, a well-tensioned wire mesh fence stands as a testament to careful planning and execution.

Wire Mesh vs Chicken Wire: Which One Matters More?

10 Questions You Should Know About Hebei Qunkun Metal Products Co., Ltd.

Brass Metal Mesh vs. Stainless Steel: Which is Superior?

Shale Shaker Screen Price in Dominican Republic: Local vs. Import

Top Shale Shaker Screen Prices in Dominican Republic

How to Choose the Perfect Metal Chain Curtain?

2024 Trends in Metal Chain Curtain Design