Crossflow Fill vs. Counterflow Fill: Which Is Better for Cooling Tower Performance?

Cooling towers are essential components of many industrial processes and HVAC systems, helping dissipate excess heat and maintain equipment efficiency. To achieve optimal cooling tower performance, the choice between two primary types of fill media—crossflow fill and counterflow fill—is a critical decision.

Understanding Cooling Tower Fill

Before delving into the comparison, let's briefly understand the purpose of fill media in cooling towers. Fill media are the heart of a cooling tower, responsible for facilitating the heat exchange process by allowing air and water to come into contact. Efficient heat exchange is essential for cooling the circulated water.

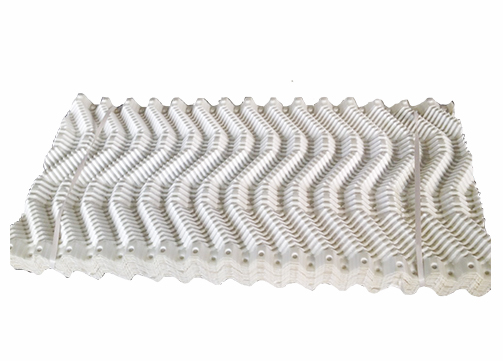

Crossflow Fill: The Pros and Cons

Advantages of Crossflow Fill:

Uniform Water Distribution: Crossflow fill is known for its ability to evenly distribute water across the fill surface, ensuring effective contact with air for efficient cooling.

Suitable for Dirty Water: Crossflow fill is less prone to clogging, making it a better choice when dealing with water sources that may contain debris or impurities.

Lower Pressure Drop: It generally has a lower pressure drop compared to counterflow fill, meaning less energy is required to circulate water through the tower.

Disadvantages of Crossflow Fill:

Larger Footprint: Crossflow towers tend to be larger in size due to the horizontal airflow pattern, which may not be suitable for sites with space constraints.

Less Efficient in Dry Climates: In dry climates, where evaporative cooling plays a crucial role, crossflow fill may be less efficient due to its horizontal airflow.

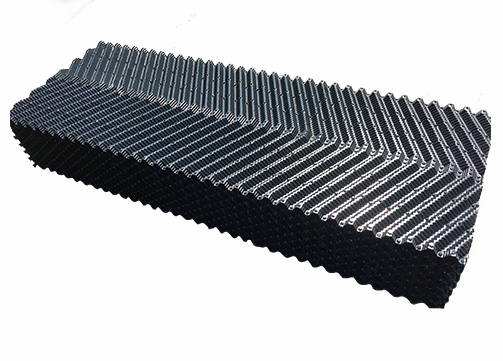

Counterflow Fill: The Pros and Cons

Advantages of Counterflow Fill:

Compact Design: Counterflow towers are more compact and take up less space, making them suitable for installations with limited area.

Higher Heat Transfer Efficiency: Counterflow fill promotes better heat transfer efficiency due to the vertical airflow pattern, which enhances the evaporative cooling process.

Energy Efficiency: In areas with a high cooling demand, counterflow towers may offer energy savings due to their superior heat transfer capabilities.

Disadvantages of Counterflow Fill:

Prone to Clogging: Counterflow fill can be more susceptible to clogging, especially when dealing with water containing suspended solids or impurities.

Uneven Water Distribution: It may face challenges in ensuring uniform water distribution across the fill surface, potentially leading to hot spots.

Choosing the Right Fill for Your Application

The choice between crossflow fill and counterflow fill largely depends on your specific application and priorities. Here are some considerations:

Space Availability: If space is limited, counterflow towers may be the preferred choice.

Water Quality: For water sources with a higher likelihood of impurities, crossflow fill is more resilient.

Energy Efficiency: In regions with high cooling demands, counterflow fill may offer better energy efficiency.

Cooling Efficiency: In dry climates, counterflow towers with their vertical airflow may provide superior cooling.

The decision between crossflow fill and counterflow fill ultimately hinges on the unique requirements of your cooling tower system. Both have their merits and drawbacks, and a careful assessment of your application's needs will help you make the right choice. Whether you prioritize space efficiency, energy efficiency, or cooling performance, the ideal fill type can be tailored to optimize your cooling tower's performance.